Characteristics of titanium spring

1. High Strength-to-Weight Ratio

Titanium springs are renowned for their exceptional strength while remaining lightweight. Titanium alloys (e.g., Ti-6Al-4V) offer tensile strength comparable to steel but at nearly half the weight, making them ideal for weight-sensitive applications.

2. Superior Corrosion Resistance

Titanium naturally forms a protective oxide layer, granting outstanding resistance to corrosion in harsh environments, including exposure to saltwater, chemicals, and extreme temperatures.

3. Fatigue Resistance

These springs exhibit excellent fatigue life, maintaining performance under cyclic loading and repetitive stress, which is critical for dynamic applications.

4. Biocompatibility

Titanium is non-toxic and biocompatible, making it suitable for medical devices and implants where contact with human tissue is required.

5. Temperature Stability

Titanium retains mechanical properties across a wide temperature range (-250°C to 600°C), ensuring reliability in both cryogenic and high-heat environments.

6. Non-Magnetic Properties

Titanium springs are non-magnetic, making them ideal for applications in sensitive electronic or medical equipment where magnetic interference must be avoided.

Applications of titanium alloy springs:

1. Aerospace & Defense

Used in aircraft landing gear, engine components, and satellite systems due to their lightweight durability and resistance to extreme conditions.

2. Medical Devices

Employed in surgical tools, orthodontic appliances, and implantable devices (e.g., pacemakers) owing to biocompatibility and corrosion resistance.

3. Automotive Engineering

Found in high-performance vehicles for valve springs, suspension systems, and fuel injection systems to reduce weight and enhance efficiency.

4. Marine & Offshore

Ideal for subsea equipment, ship components, and oil rigs where saltwater corrosion resistance is critical.

5. Sports & Consumer Goods

Used in premium bicycles, diving gear, and wearable tech to combine strength with minimal weight.

6. Industrial Machinery

Applied in precision instruments, robotics, and chemical processing equipment requiring long-term reliability under stress.

Titanium springs are a premium choice for industries demanding lightweight, durable, and corrosion-resistant solutions. Their unique properties bridge performance and longevity, particularly in high-stress, extreme, or biocompatible environments. While costlier than steel counterparts, their lifecycle value and specialized advantages justify their use in cutting-edge technologies. Welcome contact wisdom titanium for all kinds of titanium spring quotation: sales@wisdomtitanium.com

Applications

Surface treatment

Manufacturing Process

|

|

|

|

|

|

Our Factory

Wisdom Titanium was established in 2016. It is a manufacturer of custom titanium screws and titanium cncn parts, integrating development, design, sales and service. We undertake customers' own designs and orders. We propose reasonable design solutions for our customers to address non-standard screws that other manufacturers cannot produce. Our products have been exported to Europe, America and Southeast Asia all year round and have won unanimous praise from customers.

|

|

|

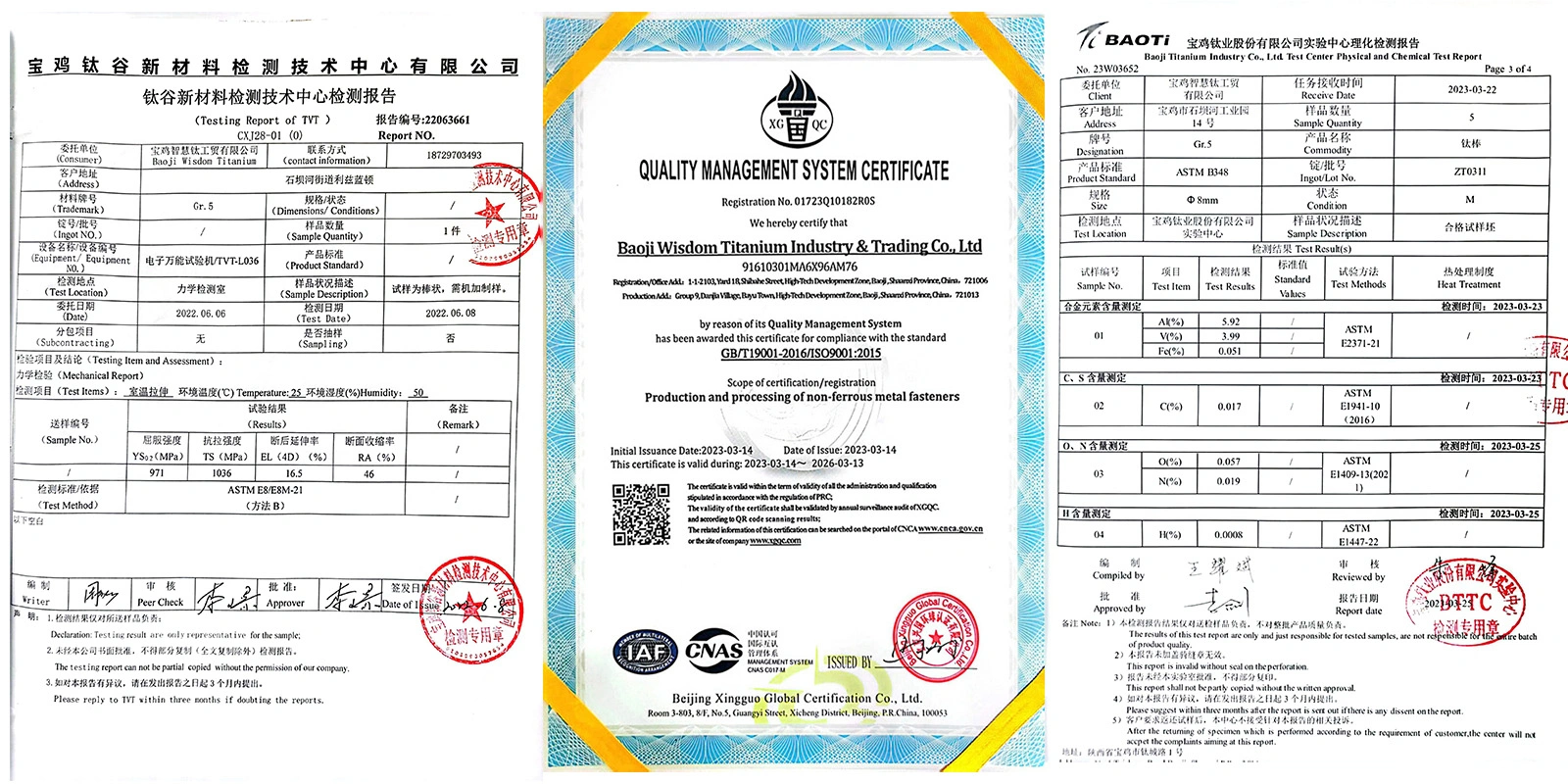

Certifications

Packing

|

|

|

|

|

|

|

|

|

|

FAQ

Q1: Do you only produce titanium screws?

We offer a wide range of titanium custom-made screws and other fasteners, as well as custom design special shaped CNC parts and welded parts. As long as you want titanium fasteners, we can customize them. Our high-quality products include custom long screws and non-standard fasteners, 12pt titanium bolts, lock nuts etc.

Q2: How do you control quality?

During the production process, each procedure is inspected at all times to ensure that the produced dimensions and appearance meet the customer's requirements. Real-time online video feedback on production progress and size inspection can be provided.

Q3: My work deadline is very tight. Could you help me?

We usually have a delivery time of 15-20 working days for all custom screw orders. For some applications, we can speed it up to 5-7 working days. Please inquire for detailed information. If you need urgent goods, please contact us.

Q4: I'm not sure which screws to use. I need a little engineering assistance. Do you offer any help?

We have a complete engineering department that provides you with the most suitable screws based on your products. Contact the engineer now.

Q5: I need custom screws, but the screws are not listed on your website. What should I do?

Our professional engineers can design professional drawings according to your needs, or produce based on the drawing or sample you provide.

Q6: What's your online contact information?

Whatsapp: +8618729703493 Instagram: @wisdomtitanium

Contact Us

E-mail:

Tel&WhatsApp: +8618729703493

_1747730734444.webp)