titanium aerospace fasteners

titanium aerospace fasteners

titanium grade 5

din933, din912, din7991, din 6921 etc.

moq: 200pcs each size

accept custom order

supply logo and surface treatment service

Product Introduction

Welcome to Baoji Wisdom Titanium Industry & Trading Co., Ltd, your premier source for titanium aerospace fasteners. With a commitment to excellence and innovation, we specialize in manufacturing high-quality titanium components tailored to meet the stringent demands of the aerospace industry.

Our titanium aerospace fasteners are engineered to provide superior performance and reliability in the most challenging environments. Titanium, renowned for its exceptional strength-to-weight ratio and corrosion resistance, is the ideal material for aerospace applications. At Wisdom Titanium, we utilize cutting-edge technology and rigorous quality control processes to ensure that each fastener meets the highest industry standards.

As a leading supplier in the titanium fasteners market, we offer a range of products including bolts, nuts, washers, and custom-designed components. Our products are designed to enhance the durability and efficiency of aerospace systems, ensuring safety and performance in flight.

Product Parameters

| Parameter | Specification |

|---|---|

| Material | Titanium Ti-6Al-4V |

| Size Range | M3 to M36 |

| Strength | Up to 1100MPa |

| Temperature Range | -250°C to 600°C |

| Surface Finish | Anodized, Polished, Coated |

| Certification | ISO 9001:2015 |

Product Advantages

-

Superior Strength-to-Weight Ratio: Titanium aerospace fasteners offer an excellent balance between strength and weight, which is critical for aerospace applications where reducing weight without compromising strength is essential.

-

Exceptional Corrosion Resistance: Titanium’s resistance to oxidation and corrosion ensures longevity and reliability in extreme environmental conditions, including high humidity and salt exposure.

-

High Temperature Tolerance: Our fasteners can withstand temperatures ranging from -250°C to 600°C, making them suitable for both cryogenic and high-temperature aerospace environments.

-

Precision Engineering: Each fastener is manufactured to precise specifications using advanced CNC machinery, ensuring a perfect fit and performance in critical applications.

-

Customizable Solutions: We offer tailored solutions to meet specific requirements, including custom sizes, coatings, and finishes, ensuring our fasteners meet the exact needs of your aerospace projects.

Product Function

Titanium aerospace fasteners play a crucial role in securing and assembling various components of aerospace systems. Their primary functions include:

- Structural Integrity: Ensuring that structural components remain firmly attached, maintaining the integrity of aircraft and spacecraft.

- Vibration Resistance: Minimizing the effects of vibration and movement, which is essential for the longevity and safety of aerospace components.

- Load Distribution: Evenly distributing loads to prevent damage and ensure the smooth operation of aerospace systems.

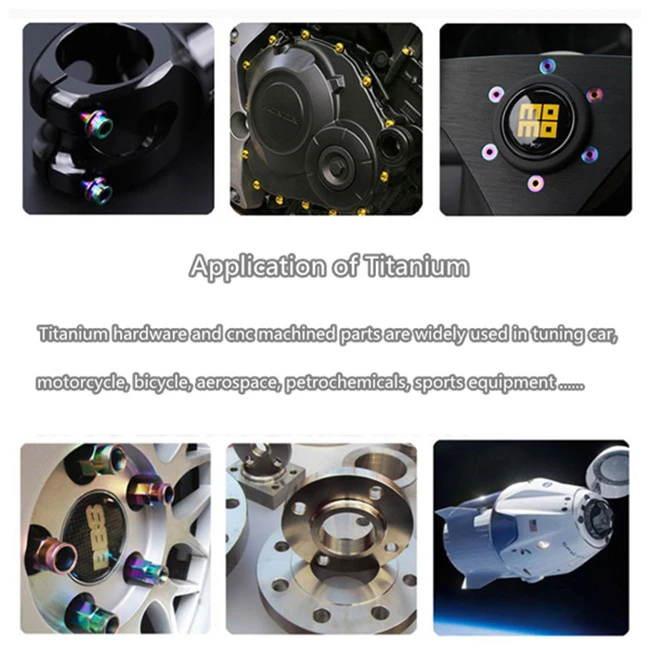

Product Applications

- Aircraft Structures: Used in the assembly of aircraft frames and wings, where strength and lightweight properties are critical.

- Spacecraft Components: Essential for securing components in spacecraft, where high strength and corrosion resistance are required.

- Engine Parts: Ideal for fasteners in jet engines and other high-temperature applications.

- Satellite Assemblies: Ensures reliable connections in satellite systems that operate in extreme environments.

|

|

|

|

|

|

|

|

|

|

The demand for titanium aerospace fasteners is increasing as the aerospace industry seeks lighter, stronger materials to improve fuel efficiency and performance. Innovations in fastener technology continue to drive advancements in aerospace engineering.

Product Craftsmanship and Production Process

Our titanium aerospace fasteners are produced through a meticulous process:

- Material Selection: We use high-grade titanium alloys, such as Ti-6Al-4V, known for their superior properties.

- Machining: Advanced CNC machines precisely cut and shape the fasteners to exact specifications.

- Surface Treatment: Fasteners undergo surface treatments including anodizing and polishing to enhance performance and durability.

- Quality Control: Rigorous testing and inspection ensure that each fastener meets our strict quality standards.Product Manufacturing Process

Our production process for DIN 7991 titanium bolts follows these steps:

- Material Sourcing: We use high-quality titanium raw materials from reliable sources.

- CNC Machining: Precision CNC machines shape the screws to exact specifications, ensuring consistent quality.

- Threading and Finishing: Threads are meticulously crafted according to ISO standards, and screws are polished or anodized for added protection and aesthetics.

- Quality Control: Each batch undergoes rigorous testing, including tensile strength, corrosion resistance, and dimensional accuracy checks.

- Packaging: Final products are carefully packed, ensuring they reach you in perfect condition.

|

|

|

|

|

|

Company Overview

Baoji Wisdom Titanium Industry & Trading Co., Ltd, established in 2013, is an ISO 9001-certified manufacturer and supplier of titanium aerospace fasteners. We serve a diverse range of industries including aerospace, energy, medical, and automotive. Our expertise extends to producing titanium fasteners, CNC parts, and custom solutions.

Our facility is equipped with state-of-the-art machinery and staffed by experienced professionals dedicated to producing high-quality components. We adhere to international standards, ensuring product excellence and customer satisfaction.rance

|

|

|

Logistics and Packaging

- Wooden Crate Packaging: Provides secure and durable protection for large orders.

- Carton Packaging: Suitable for smaller quantities, with adequate cushioning.

- Foam Filling: Ensures that each fastener is protected from impact and damage during transit.

- Waterproof and Moisture-Proof Packaging: Protects against environmental factors during shipping.

- Custom Packaging: Tailored to meet specific client needs and preferences.

|

|

|

|

|

|

|

|

|

|

Logistics:

- Sea Freight: Cost-effective for bulk orders.

- Air Freight: Ideal for expedited deliveries.

- Land Transport: Reliable for regional deliveries.

- Multi-modal Transport: Combines different transportation methods for efficiency.

- Courier Services: Fast delivery for urgent orders.

Why Choose Us

- Quality Assurance: Our products meet ISO 9001 standards, ensuring high quality and reliability.

- Experience and Expertise: With over a decade in the industry, we have extensive knowledge and experience in titanium manufacturing.

- Custom Solutions: We offer OEM/ODM services to meet your specific needs.

- Comprehensive Inventory: A complete stock of raw materials and parts with stable pricing.

- Customer-Centric Approach: We value customer feedback and continuously improve our products based on your input.

OEM Services

At Baoji Wisdom Titanium, we support customized processing services. Whether you need specific designs, sizes, or finishes, our experienced team can create tailored solutions to meet your exact requirements. From concept to final product, we ensure that your specifications are met with precision.

FAQ

-

What types of titanium are used in aerospace fasteners?

- We primarily use Ti-6Al-4V, known for its strength and durability.

-

Can I get custom sizes and designs?

- Yes, we offer custom OEM services to meet your specific requirements.

-

What is the typical lead time for orders?

- Lead times vary based on order size and customization but typically range from 2 to 6 weeks.

-

Do you offer international shipping?

- Yes, we provide shipping services worldwide through various logistics methods.

-

What are your quality control measures?

- We conduct rigorous testing and inspection throughout the production process to ensure product quality.

Contact Us

For more information on our titanium aerospace fasteners or to discuss your specific needs, please contact us at sales@wisdomtitanium.com. We look forward to collaborating with you and providing the best solutions for your aerospace projects.

_1753415045272.webp)

_1753415036360.webp)

_1753415010840.webp)

_1753414979984.webp)

_1753414965185.webp)