Mini titanium screw

Mini titanium screw

M1.2-M3

Titanium grade 5

flat head/cap head/button head etc.

moq: 200pcs each size

lead time:10-15days

payment: bank transfer/paypal

Mini titanium screw

Material | Titanium alloy (Ti-6Al-4V Grade 5)

M0.6 - M3.0 (Customization supported)

Length range : 1mm - 20mm

Surface treatment : Anodizing/Sandblasting/PVD coating

Tensile strength : ≥900 MPa

Temperature resistance range : -200°C to +450°C

Mini titanium screw features:

- High strength titanium alloy gr5

It adopts aerospace-grade titanium alloy (Ti-6Al-4V), with strength comparable to that of steel, 50% lighter in weight, tensile strength ≥900 MPa, and excellent fatigue resistance.

- Ultra-precision machining technology

Precisely manufactured by CNC lathes, with a tolerance range of ±0.01mm and a surface finish Ra≤0.8μm, it ensures perfect adaptation to the requirements of high-precision equipment.

- Extreme corrosion resistance **

It has passed the 72-hour salt spray test, is antioxidant and resistant to acids and alkalis, and is suitable for harsh environments such as medical care and Marine applications.

- Biocompatibility certification **

It complies with the ISO 10993 medical-grade standard and is safely used for human implantable devices and surgical equipment.

Application of Mini titanium screw

Medical field

Core components of orthopedic implant screws, dental restoration instruments, and minimally invasive surgical equipment.

Precision instruments

The internal structures of optical instruments, micro-sensors and high-precision clocks are fixed.

Electronic devices

Micro drones, smart wearable devices, and micro camera modules are concealed and securely fastened.

Aerospace

Assembly of satellite micro-components and fixation of lightweight structures for model aircraft.

Common Questions

Q: What is the minimum order quantity (MOQ)?

A: We support small-batch purchases. The standard parts MOQ is 100 pieces and the custom parts MOQ is 500 pieces.

Q: Is anti-magnetic treatment provided?

A: Supports special magnetic shielding coatings to meet the requirements of medical scenarios such as MRI.

Q: How can we ensure that it doesn't rust over long-term use? **

A: Titanium alloys come with their own passivation films. Combined with anodic oxidation treatment, they can prevent rust for a lifetime

|

|

|

|

|

|

Our Factory

Wisdom Titanium was established in 2016. It is a manufacturer of custom titanium screws and titanium cncn parts, integrating development, design, sales and service. We undertake customers' own designs and orders. We propose reasonable design solutions for our customers to address non-standard screws that other manufacturers cannot produce. Our products have been exported to Europe, America and Southeast Asia all year round and have won unanimous praise from customers.

|

|

|

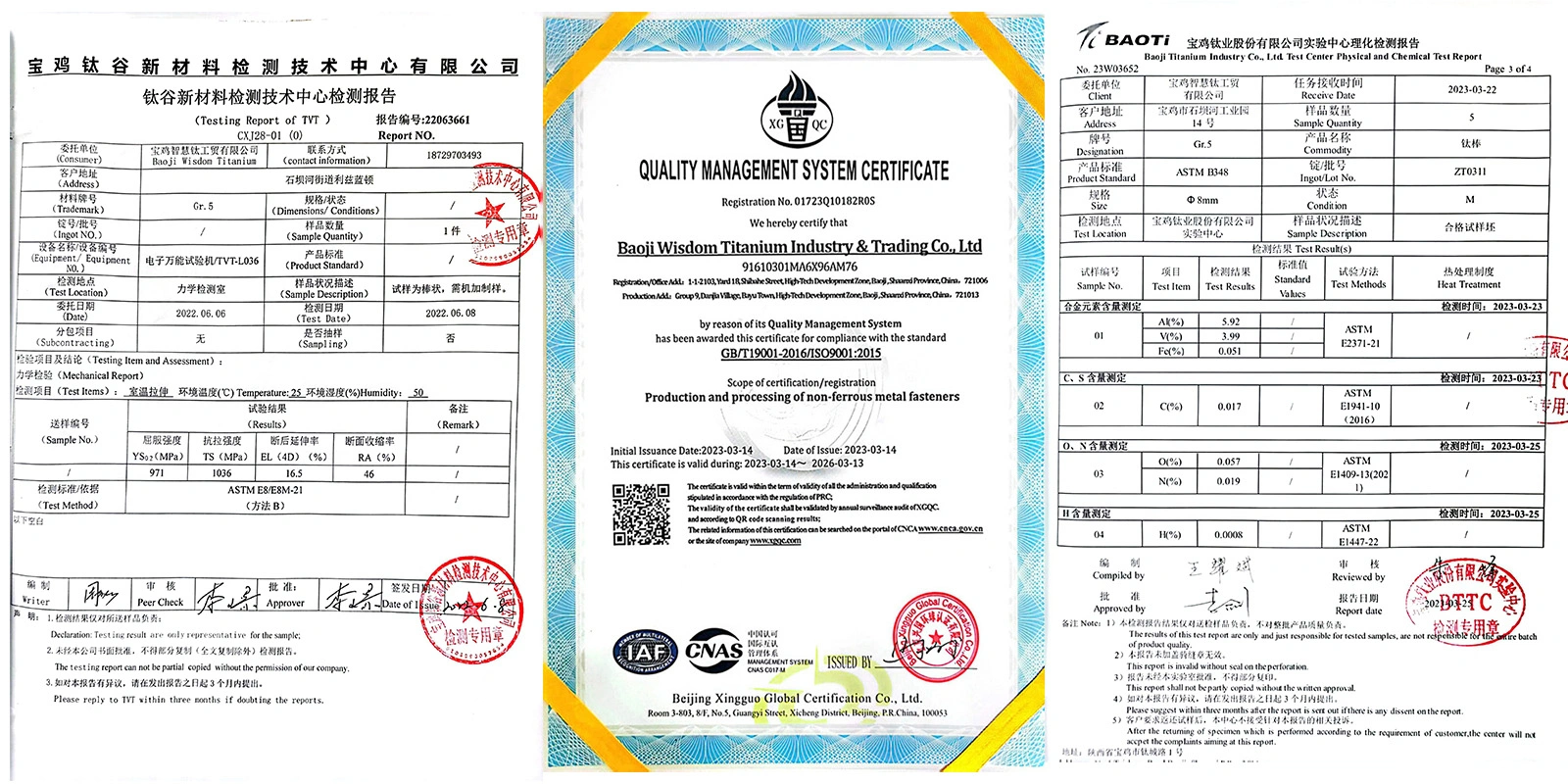

Certifications

Packing

|

|

|

|

|

|

|

|

|

|

Surface treatment of mini titanium screw

FAQ

Q1: Do you only produce titanium screws?

We offer a wide range of titanium custom-made screws and other fasteners, as well as custom design special shaped CNC parts and welded parts. As long as you want titanium fasteners, we can customize them. Our high-quality products include custom long screws and non-standard fasteners, 12pt titanium bolts, lock nuts etc.

Q2: How do you control quality?

During the production process, each procedure is inspected at all times to ensure that the produced dimensions and appearance meet the customer's requirements. Real-time online video feedback on production progress and size inspection can be provided.

Q3: My work deadline is very tight. Could you help me?

We usually have a delivery time of 15-20 working days for all custom screw orders. For some applications, we can speed it up to 5-7 working days. Please inquire for detailed information. If you need urgent goods, please contact us.

Q4: I'm not sure which screws to use. I need a little engineering assistance. Do you offer any help?

We have a complete engineering department that provides you with the most suitable screws based on your products. Contact the engineer now.

Q5: I need custom screws, but the screws are not listed on your website. What should I do?

Our professional engineers can design professional drawings according to your needs, or produce based on the drawing or sample you provide.

Q6: What's your online contact information?

Whatsapp: +8618729703493 Instagram: @wisdomtitanium

Contact Us

E-mail:

Tel&WhatsApp: +8618729703493

_1745572067353.webp)