Drone Titanium Screw

ISO 7380 titanium screw

titanium grade 5

m2*4/5/6/7/12

moq: 200pcs

Product Introduction

Drone titanium screws are essential fastening components designed specifically for Unmanned Aerial Vehicles (UAVs). These screws offer exceptional performance by combining lightweight properties with high strength, making them an ideal choice for aerospace applications where weight reduction and durability are paramount. Manufactured from premium-grade titanium alloys, such as Ti-6Al-4V (Grade 5), these screws exhibit excellent corrosion resistance, fatigue strength, and thermal stability, ensuring long-lasting performance in demanding environments.

Titanium screws play a crucial role in drone assembly, securing critical components such as frames, motors, and electronic modules. Unlike steel or aluminum fasteners, drone titanium screw provide a superior strength-to-weight ratio, minimizing the overall weight of the drone while maintaining structural integrity. The use of high-quality titanium screws enhances flight efficiency, improves aerodynamics, and increases battery life due to reduced overall weight.

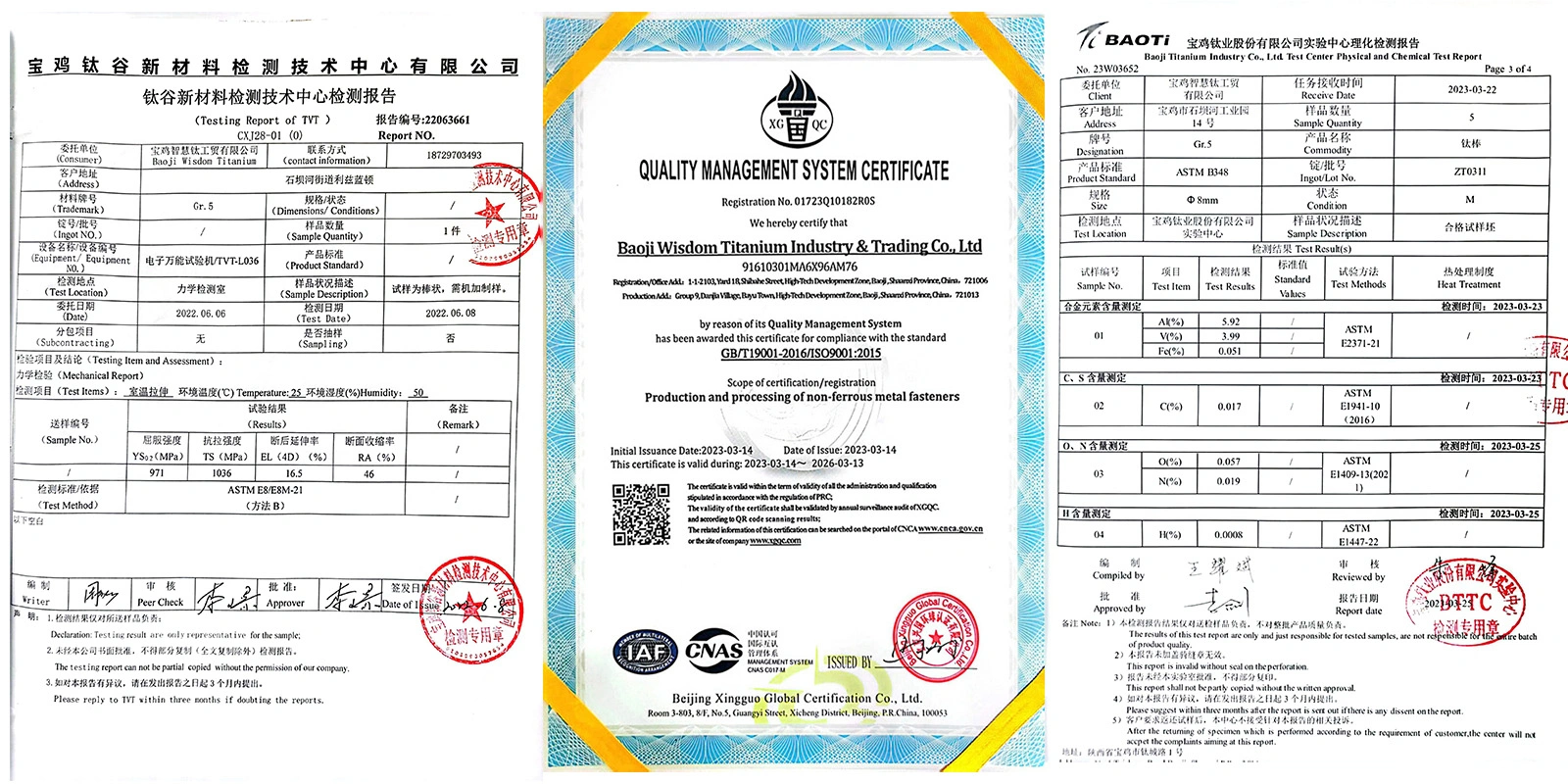

As a professional manufacturer and supplier of titanium screws, we offer various standard and customized options tailored to meet specific application requirements. Our products undergo rigorous testing and certification processes, ensuring compliance with international standards and industry specifications. Additionally, we provide full testing reports, OEM support, and fast delivery, making us the preferred choice for global drone manufacturers and UAV component suppliers.

Product Standards

drone titanium screw

ISO 7380 titanium screw

titanium grade 5

m2*4/5/6/7/12mm

moq: 200pcs

Basic Parameters

| Parameter | Specification |

|---|---|

| Material | Titanium Alloy (Ti-6Al-4V, Grade 5) |

| Tensile Strength | ≥ 895 MPa |

| Yield Strength | ≥ 828 MPa |

| Hardness | 36 HRC (approx.) |

| Density | 4.43 g/cm³ |

| Operating Temperature | -253°C to 600°C |

| Corrosion Resistance | Excellent (Salt, Acid, Alkali) |

| Standard Compliance | ASTM, ISO, DIN, JIS, GB/T |

Functions:

Secure drone frame components and electronic modules

Provide lightweight yet strong fastening for UAVs

Improve drone structural integrity and vibration resistance

Enhance aerodynamics by reducing unnecessary weight

Features:

High strength-to-weight ratio for improved performance

Excellent corrosion resistance in harsh environments

Thermal stability for high-temperature applications

Low magnetic permeability for precision instruments

Precision threading for secure and vibration-resistant fastening

Advantages:

Weight reduction enhances flight efficiency and battery life

Corrosion-resistant properties ensure longevity in all weather conditions

Customization options cater to specific UAV designs and requirements

Superior fatigue strength extends operational lifespan

Compliance with industry standards guarantees reliability and quality

Application Areas

| Industry | Application |

| Aerospace | UAV assembly, aerospace fastening |

| Military Drones | Secure electronic and optical systems |

| Commercial Drones | Agriculture, surveying, photography |

| Industrial UAVs | Inspection, logistics, cargo drones |

| Research & Development | Prototyping, testing advanced drone designs |

|

|

|

|

|

|

|

|

|

|

Manufacturing Process

|

|

|

|

|

|

Our Factory

|

|

|

Certifications

Packing

|

|

|

|

|

|

|

|

|

|

OEM Services

We offer comprehensive OEM and customization services, including:

Custom screw dimensions, threading, and head types

Special surface treatments and coatings (anodization, passivation)

Private labeling and bulk order packaging solutions

Fast prototyping and mass production capabilities

Technical support and quality control verification

FAQ

Q1: What are the benefits of using titanium screws in drones? A1: Titanium screws offer superior strength while being lightweight, improving flight performance, battery efficiency, and durability.

Q2: Do you provide customized titanium screws? A2: Yes, we offer a wide range of customization options, including different sizes, threading types, and coatings.

Q3: What certifications do your titanium screws meet? A3: Our products comply with ASTM, ISO, DIN, JIS, and GB/T standards and come with full certification reports.

Q4: Can I request samples before placing a bulk order? A4: Yes, we provide sample orders for quality evaluation before bulk production.

Q5: What is your lead time for bulk orders? A5: Standard sizes are available for fast delivery, while customized orders typically require 2-4 weeks depending on complexity.

Contact Us

Wisdom Titanium – Your Trusted Partner for High-Quality Titanium Fasteners

Email: sales@wisdomtitanium.com

We are a professional manufacturer and supplier of titanium screws, providing various standard and customized options. Our products are backed by certifications, complete test reports, OEM support, fast delivery, and secure packaging. If you need premium-quality titanium screws for UAV applications, feel free to contact us today!