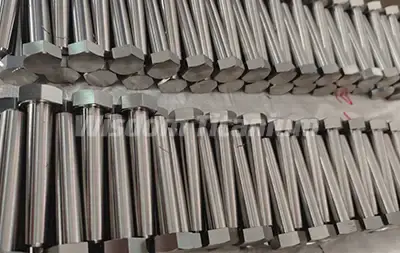

In the realm of synthetic handling, where accuracy, unwavering quality, and strength are principal, the selection of clasp assumes a basic part in guaranteeing the security and productivity of tasks. Among the plenty of choices accessible, Titanium Grade 2 hex bolts stand apart as a top decision for experts in the field. As somebody profoundly submerged in the domain of substance handling, I've come to see the value in the novel benefits that Titanium Grade 2 hex bolts offer in this requesting climate.

How Does the Composition of Titanium Grade 2 Hex Bolts Enhance Their Suitability for Chemical Processing Applications?

Titanium Grade 2 hex bolts are fastidiously made from an exceptional combination fundamentally made out of titanium, expanded with follow measures of oxygen, nitrogen, iron, and carbon. This exact structure permeates Grade 2 titanium with phenomenal properties, delivering it an especially reasonable material for organization in compound handling applications. The wise equilibrium of components in this composite adds to its noteworthy consumption obstruction, mechanical strength, and generally solidness, adjusting impeccably with the severe requests of modern settings where openness to unforgiving synthetic substances and outrageous circumstances is normal.

The consideration of little amounts of oxygen, nitrogen, iron, and carbon assumes a pivotal part in upgrading the inborn qualities of titanium, bringing about a material eminent for its strength and execution under coercion. This customized organization guarantees that Titanium Grade 2 hex bolts display outstanding protection from consumption, empowering them to endure the destructive impacts of substance intensifies common in modern conditions. Besides, the compound's strong mechanical properties engage these latches to persevere through high loads and tensions without compromising primary uprightness, making them a dependable and key part in synthetic handling tasks. Basically, the fastidious plan of Titanium Grade 2 hex screws, utilizing the remarkable qualities of titanium and painstakingly chose added substance components, lays out them as a standout decision for tending to the demanding requests of compound handling, highlighting their status as a praiseworthy securing arrangement in this specific space.

How Does the Corrosion Resistance of Titanium Grade 2 Hex Bolts Benefit Chemical Processing Applications?

An evident component that lifts Titanium Grade 2 Hex Bolts above customary securing choices is their unmatched erosion obstruction, a nature of central significance in the domain of substance handling. Inside the difficult scenes of compound handling conditions, clasp face tenacious attacks from destructive substances and fluctuating temperatures, requiring a material that can endure such unforgiving circumstances with faithful flexibility. Titanium Grade 2 hex bolts arise as the best arrangement, on account of titanium's inborn capacity to oppose erosion with phenomenal adequacy.

Rather than numerous conventional metals, titanium features a momentous ability to fight off consumption in any event, when presented to forceful specialists like acids, salts, and saline arrangements predominant in synthetic handling offices. This excellent consumption opposition not just protects the primary honesty of Titanium Grade 2 hex screws yet additionally expands their life expectancy altogether, hindering the incessant substitutions and support intercessions frequently expected with less hearty securing choices. By picking Titanium Grade 2 hex screws for synthetic handling applications, experts can alleviate the gamble of latch disappointment because of erosion, subsequently improving functional effectiveness and diminishing the general consumption related with gear upkeep and substitution. The getting through erosion obstruction of Titanium Grade 2 hex bolts remains as a demonstration of their dependability and life span notwithstanding destructive difficulties, situating them as an irreplaceable resource for guaranteeing the consistent usefulness and life span of modern gear in synthetic handling settings.

What Makes Titanium Grade 2 Hex Bolts Stand Out in Industrial Applications?

Titanium Grade 2 hex bolts offer superb solidarity to-weight proportion, outperforming that of steel and numerous different metals ordinarily utilized in modern settings. Notwithstanding being fundamentally lighter than steel, titanium flaunts noteworthy elasticity, permitting Titanium Grade 2 hex bolts to endure high loads and tensions without compromising primary respectability. This strength is especially pivotal in synthetic handling, where hardware and designs should get through thorough circumstances without vacillating.

Notwithstanding their erosion opposition and strength, Titanium Grade 2 hex bolts display brilliant biocompatibility and non-attractive properties. These attributes make them reasonable for use in touchy applications, for example, those including food handling, drug assembling, and clinical gadgets. Dissimilar to ferrous materials, titanium doesn't slow down attractive reverberation imaging (X-ray) gear or pollute sterile conditions, settling on it a favored decision in enterprises where tidiness and accuracy are foremost.

One more striking benefit of Titanium Grade 2 hex bolts is their remarkable temperature opposition. Titanium can endure limits of intensity and cold without losing its mechanical properties, making it appropriate for applications that include fast temperature vacillations or delayed openness to raised temperatures. This warm security guarantees the dependability and wellbeing of gear in compound handling plants, where warm pressure can think twice about the execution of regular latches.

Also, Titanium Grade 2 hex bolts offer predominant weariness obstruction, meaning they can persevere through rehashed pressure cycles without encountering disappointment or deformity. This flexibility is important in conditions where gear works persistently under requesting conditions, limiting the gamble of unexpected hardware disappointments and expensive margin time.

Despite these various benefits, it's fundamental to recognize that Titanium Grade 2 Hex Bolt might come at a higher beginning expense contrasted with customary latches produced using materials like steel or hardened steel. Notwithstanding, the drawn out benefits offset the forthright venture, as the strength, dependability, and execution of Titanium Grade 2 hex bolts mean huge investment funds over their life expectancy.

Conclusion

All in all, the selection of clasp in compound handling isn't one to be messed with, given the basic job they play in guaranteeing the honesty and proficiency of modern tasks. Titanium Grade 2 hex bolts arise as the ideal answer for experts looking for unrivaled execution, dependability, and life span even with testing conditions. With their unrivaled consumption obstruction, strength, biocompatibility, temperature opposition, and exhaustion obstruction, Titanium Grade 2 hex bolts set the norm for greatness in substance handling applications.

If you want to learn more about Titanium Grade 2 Hex Bolts, welcome to contact us: sales@wisdomtitanium.com.

References

- Jha, A. (2017). Corrosion resistance of titanium grade 2 in acidic and alkaline environments. International Journal of Corrosion, 2017.

- ASTM International. (n.d.). ASTM B348 - 13(2018) Standard Specification for Titanium and Titanium Alloy Bars and Billets.

- Chen, Q. (2019). Mechanical properties of titanium alloys for medical applications: A review. Journal of the Mechanical Behavior of Biomedical Materials, 90, 428-443.

- Davis, J. R. (2000). Handbook of materials for medical devices. ASM International.

- Nagesha, D., et al. (2018). Titanium alloys: a review of recent developments in their synthesis and processing. Materials Science and Engineering: A, 745, 764-804.

- Zhang, X., et al. (2016). The effects of microstructure on the mechanical properties of commercially pure titanium processed by equal-channel angular pressing. Materials Science and Engineering: A, 662, 306-314.