Titanium torx bolts are a paragon of engineering excellence, combining the extraordinary properties of titanium with the practical design of torx heads. These fasteners are lauded for their impressive strength-to-weight ratio, corrosion resistance, and durability. But what exactly are the specifications that make these bolts so sought-after in various industries? Let's delve into the nitty-gritty details of titanium torx bolts and explore their key specifications.

Thread Diameter

The thread diameter of titanium torx bolts is a crucial specification that determines their application and load-bearing capacity. These bolts are available in a wide range of diameters to suit different needs:

- Metric sizes typically range from M4 to M30

- Imperial sizes are also available, ranging from #4 to 1-1/4 inches

The choice of thread diameter depends on several factors:

- The load the bolt needs to bear

- The thickness of the materials being fastened

- The space available for the bolt

- The specific requirements of the application

For instance, smaller M4 or M5 titanium torx head bolts might be used in electronics or lightweight aerospace applications, while larger M20 or M30 bolts could be employed in heavy machinery or structural engineering projects.

It's worth noting that the thread pitch, which is the distance between thread crests, is also an important consideration. Fine threads (with smaller pitch) provide greater tensile strength and resistance to vibration loosening, while coarse threads are easier to install and remove.

Thread Length

The thread length of titanium torx bolts is another vital specification that affects their performance and suitability for different applications. The thread length can vary significantly, typically ranging from 6mm to 150mm, though custom lengths can be manufactured for specific needs.

Several factors influence the choice of thread length:

- The thickness of the materials being joined

- The required engagement length for optimal strength

- The need for additional length for nuts or locking devices

- Specific design requirements of the application

It's crucial to select the appropriate thread length to ensure proper engagement and load distribution. A thread engagement of at least 1.5 times the bolt diameter is often recommended for optimal strength, though this can vary based on the specific application and materials involved.

For example, a titanium allen head bolt with a 10mm diameter might have a thread length of 15-20mm for general applications, but could be much longer for specialized uses where deeper engagement is necessary.

Interestingly, some titanium torx bolts feature partially threaded shanks, where only a portion of the bolt's length is threaded. This design can be advantageous in certain applications, providing a smooth bearing surface and potentially increasing shear strength.

Head Size

The head size of titanium torx bolts is a critical specification that affects both their functionality and aesthetics. The torx head design, characterized by its six-pointed star shape, offers several advantages over traditional hex heads:

- Better torque transfer

- Reduced risk of cam-out (slippage during tightening)

- Lower wear on both the bolt and the tool

- Improved aesthetic appeal in visible applications

Titanium torx bolt heads typically come in standard sizes corresponding to their thread diameter. For instance:

- M4 bolts often use a T20 head size

- M5 bolts might use a T25 head

- M6 bolts could use a T30 head

- Larger bolts like M8 or M10 might use T40 or T50 heads

The head diameter and height are also important considerations. For example, a titanium dome head bolt might have a larger head diameter relative to its thread size, providing a larger bearing surface. On the other hand, a low-profile or countersunk head design might be preferred in applications where a flush surface is required.

It's worth noting that some specialized applications might use custom head sizes or designs. For instance, a titanium banjo bolt used in hydraulic systems would have a unique head design with a hollow center to allow fluid flow.

The choice of head size and design can significantly impact the bolt's performance, ease of installation, and overall aesthetics of the finished product. Therefore, it's crucial to consider these factors when selecting titanium torx bolts for a specific application.

Material Grade and Strength

While not a dimensional specification, the material grade of titanium used in torx bolts is a crucial factor that determines their performance characteristics. The most commonly used grade for these bolts is Grade 5 (Ti-6Al-4V), which offers an excellent balance of strength, weight, and corrosion resistance.

Grade 5 titanium bolts typically have:

- Tensile strength above 1000 MPa

- Yield strength around 830 MPa

- Elongation of 10% or more

These properties make Grade 5 titanium torx bolts suitable for a wide range of applications, from aerospace to marine environments. However, other grades like Grade 2 (commercially pure titanium) or Grade 23 (ELI Ti-6Al-4V) might be used for specific requirements.

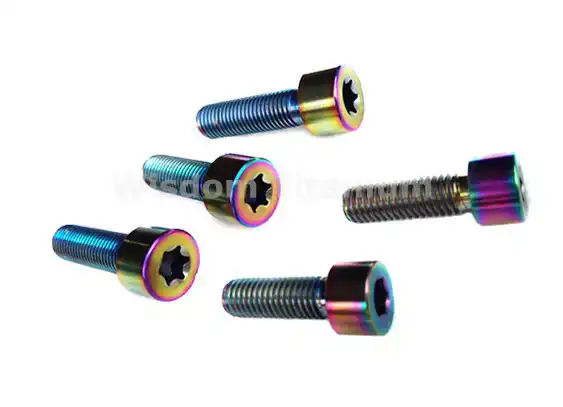

Finish and Coatings

Titanium torx bolts can be supplied with various finishes or coatings to enhance their properties or appearance:

- Natural (uncoated) finish

- Anodized finishes in various colors

- Dry film lubricant coatings for reduced friction

- Ceramic coatings for extreme temperature applications

The choice of finish can affect not only the bolt's appearance but also its performance characteristics such as corrosion resistance, friction coefficient, and galling resistance.

Temperature Range

Titanium torx bolts are known for their wide operating temperature range. Typical Grade 5 titanium bolts can operate effectively from cryogenic temperatures as low as -250°C up to about 400°C. This broad temperature range makes them suitable for use in diverse environments, from aerospace applications to cryogenic equipment.

Corrosion Resistance

One of the standout features of titanium torx bolts is their excellent corrosion resistance. They are particularly resistant to:

- Saltwater and marine environments

- Many acids and alkalis

- Chlorine and chloride solutions

This makes them ideal for use in harsh environments where steel or even stainless steel fasteners might fail due to corrosion.

Titanium Torx Bolts Supplier

Wisdom Titanium offers high-quality titanium Torx bolts, which are made from Titanium Grade 5. These bolts feature a thread size range of M4 to M30, with head types specifically designed in Torx. They are available in lengths from 6mm to 150mm and diameters from 2mm to 12mm. These bolts have a strength above 1000 MPa and excellent corrosion resistance. They come in natural or anodized finishes and can operate within a temperature range of -250°C to 400°C. For more information or inquiries, please contact us at sales@wisdomtitanium.com.

References

- Johnson, R. (2021). "Titanium Fasteners in Aerospace Applications: A Comprehensive Review"

- Smith, A. et al. (2020). "Comparative Study of Torx vs Hex Head Bolts in High-Stress Environments"

- Zhang, L. (2022). "Corrosion Resistance of Titanium Alloys in Marine Environments"

- Brown, T. (2019). "Thread Specifications for High-Performance Titanium Fasteners"

- Garcia, M. (2023). "Advancements in Titanium Bolt Manufacturing Techniques"

- Wilson, K. (2021). "Temperature Effects on Titanium Fastener Performance: From Cryogenic to Extreme Heat"