Buying fasteners across borders feels simple until the first shipment arrives and something does not match: the thread fit is tight, the surface finish looks off, or the paperwork cannot support your audit. A titanium flange nut often sits in critical joints, on aircraft interiors, offshore platforms, chemical skids, racing motorcycles, and medical equipment frames, so small gaps can become large risks.

This guide follows the real path most buyers take: you find an article, you browse, you hesitate, then you look for proof and consistency before you send an inquiry. We will focus on what matters globally: standards, material grade, traceability, corrosion performance, manufacturing controls, and supplier reliability.

Global specs and compliance: what you must verify before pricing

Start with the drawing, then lock the standard

Global sourcing works when the specification is unambiguous. Many flange nuts look similar in photos, yet differ in flange diameter, bearing surface, chamfer details, wrenching features, and thread tolerance. Before you compare quotes, define which standard your assembly accepts, or confirm “per drawing” with a controlled revision.

In cross-border procurement, the most common mismatch comes from assuming that “equivalent” standards are interchangeable. ISO and DIN fasteners often align closely, while ASME/ANSI dimensions can differ. Threads are another trap. Metric threads (ISO) and Unified threads (UNC/UNF) do not substitute, and even within the same nominal size, tolerance classes change fit and performance.

Material designation: Do not accept “Ti” as an answer

“Titanium” is not one material. For many high-strength applications, buyers specify titanium grade 5 (Ti-6Al-4V), which is widely used in aerospace and high-performance engineering due to its strength-to-weight ratio. Yet the grade must appear on the mill test documentation and remain traceable through production.

Ask your titanium flange nut supplier to confirm the grade, the form of starting material (rod), and traceability to heat/lot numbers. For regulated industries, this paperwork is not optional. If you need special requirements—like restricted chemistry ranges, grain flow expectations, or hardness limits—state them early.

Certifications and documentation that reduce audit stress

Certifications do not replace inspection, but they reduce uncertainty. For most industrial buyers, an ISO 9001 quality management system helps standardize process control, calibration, and corrective actions. If your project faces audits, confirm that the supplier can provide: material certificates (often called MTRs), dimensional inspection records, and packaging labels that preserve lot identity.

Baoji Wisdom Titanium Industry and Trading Co., Ltd is an ISO 9001-certified manufacturer and supplier of standard and customized CNC parts. Our titanium fasteners are produced from high-quality titanium rods, with detection before shipment, and we treat customer feedback as part of continuous improvement.

Performance, reliability, and real-world risks in the titanium flange nut supply

Corrosion resistance is strong, but the environment still matters

Titanium is known for forming a stable oxide film, which supports strong corrosion resistance in many natural and industrial environments. That said, performance depends on the full system: the mating bolt material, crevice conditions, temperature, and the presence of aggressive chemicals. For marine engineering and chemical processing, buyers often select titanium specifically to reduce corrosion-driven maintenance. Still, good purchasing decisions include a quick check of service media and temperature range.

If your assembly combines dissimilar metals, discuss galvanic considerations and isolation strategies with your engineering team. Procurement should not guess; it should confirm.

Strength, preload, and friction: where “good enough” fails

Flange nuts spread the load over a larger bearing area, which can help protect softer materials and reduce the need for washers. But joint integrity depends on preload. Preload depends on friction. Friction depends on surface condition, coating (if any), lubrication practices, and thread quality.

When purchasing globally, insist on consistent surface finish and thread control because they stabilize torque-tension behavior. If your application uses torque-only methods, variability in friction can cause scatter in clamp load. In higher-risk projects, buyers often define installation methods and lubrication rules in the assembly spec.

Manufacturing quality: the hidden difference between suppliers

A titanium flange nut can be produced by machining or by forming, plus finishing steps. Either method can succeed when the supplier controls the process. Problems appear when tools wear, threads are cut too aggressively, or inspection is rushed. Those issues do not always show in a single sample. They show consistency across lots.

Ask about in-process inspection, gauges for thread verification, and how the supplier manages nonconforming parts. Also, ask how they protect parts during packing, because titanium surfaces can pick up scratches and dents that affect the assembly feel and customer confidence.

Counterfeit risk and “paper-only” compliance

Global fastener markets face a known risk: documentation that does not match the physical product. The simplest defense is traceability and repeatable controls. Request heat/lot traceability, confirm that paperwork matches labels, and keep incoming inspection active. For critical programs, consider periodic supplier audits or third-party inspections.

How to evaluate a global titanium flange nut supplier and move from hesitation to confidence?

Supplier location and ecosystem: why Baoji Titanium Valley matters

Many buyers evaluate a supplier only by price and lead time. A better filter is the manufacturing ecosystem behind the quote. Baoji Titanium Valley, located in Shaanxi Province, is China’s largest and most comprehensive titanium industry cluster—and one of the most influential titanium production bases globally. It covers a complete chain: titanium sponge, ingots, bars, plates, tubes, forgings, and high-performance titanium alloys. This depth supports stable sourcing and strong technical support.

The region hosts hundreds of titanium and titanium-alloy enterprises. It supplies major sectors such as aerospace, marine engineering, petrochemicals, medical implants, energy, and high-end equipment manufacturing. With growing exports to Europe, North America, Southeast Asia, and the Middle East, Baoji has built international recognition as a major supplier base for titanium products.

What Baoji Wisdom Titanium can supply (and how to specify it clearly)

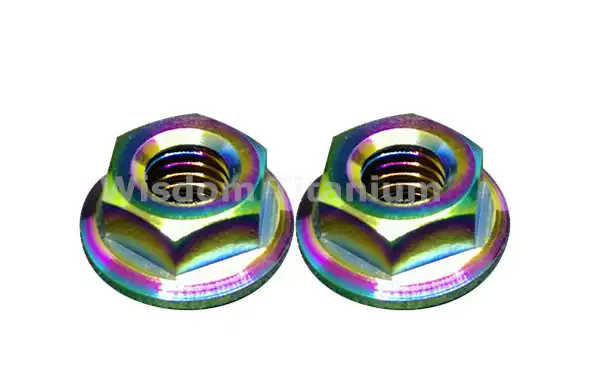

Baoji Wisdom Titanium focuses on titanium fasteners and customized CNC parts. For titanium flange nuts, we supply: titanium hex flange nuts, titanium 12pt flange nuts, and titanium flange lock nuts. Titanium grade options include titanium grade 5, a common choice for strength-critical designs.

To keep quoting fast and accurately, include your drawing or standard, thread type and pitch, quantity per size, and any inspection or documentation needs. Our MOQ is 200 pcs each. If you have samples, we can reference them during development. If you have an idea but no finished drawing, share the application constraints and we will discuss a practical route.

Lead time, communication rhythm, and after-sales response

The best suppliers communicate like partners. You should expect clear confirmations on specs, realistic production scheduling, and quick clarification when a requirement conflicts with a standard. Baoji Wisdom Titanium maintains a complete inventory of raw materials and standard parts with stable prices. We use mature production technology with whole-process follow-up detection. These habits support predictable lead time and stable quality.

After delivery, responsiveness still matters. If a buyer reports a fit issue or packaging damage, the titanium flange nut supplier should treat it as a system signal, not a one-time complaint. We take customer feedback seriously and use it to improve products in time.

From “browsing” to “inquiry”: a simple checklist that saves weeks

If you are at the hesitation stage, use this short checklist before you send an RFQ. It forces clarity and reduces back-and-forth.

- Confirm standard or drawing revision, including flange dimensions and wrenching features.

- Confirm thread system (metric or unified), pitch, tolerance class, and fit expectation.

- Confirm grade (for example, titanium grade 5) and any special chemistry or mechanical limits.

- Define inspection: thread gauging, dimensional report, and packaging label traceability.

- State quantity per size (MOQ: 200 pcs each) and delivery destination.

If you want a quotation from Baoji Wisdom Titanium, email your requirements to sales@wisdomtitanium.com. Include the checklist items above and your target delivery window.

FAQs

Q1: What should I include in an RFQ for a titanium flange nut?

A: Include the standard or drawing, thread type and pitch, size, quantity per size, material grade (such as titanium grade 5 if required), inspection/document needs, and shipping destination. If you need a specific nut style, note it clearly: titanium hex flange nuts, titanium 12pt flange nuts, or titanium flange lock nuts.

Q2: Why do global purchases fail even when the sample looks correct?

A: Samples can hide process variation. The risk shows up across lots. Thread tolerance, surface finish, tool wear, and inspection discipline drive consistency. Ask for traceability, defined inspection records, and stable process controls under ISO 9001.

Q3: Is titanium grade 5 suitable for high-strength flange nut applications?

A: Many buyers choose titanium grade 5 (Ti-6Al-4V) when they need high strength with low weight. Suitability still depends on your joint design, preload method, temperature, and environment. Share the application details during inquiry so the supplier can confirm feasibility.

Q4: What is the minimum order quantity at Baoji Wisdom Titanium?

A: The MOQ is 200 pcs each. If you have multiple sizes, specify the quantity for each size in the RFQ.

Q5: Can Baoji Wisdom Titanium support custom designs beyond standard flange nuts?

A: Yes. We supply standard and customized CNC parts and can develop products based on your samples or idea. Alongside titanium fasteners, we also produce parts in Nickel, tantalum, and zirconium, and supply titanium rods, flange, and forging.

References

- International Organization for Standardization (ISO) – ISO standards overview

- ASTM International – Standards and materials guidance (titanium alloys and fastener-related standards catalog)

- SAE International – Aerospace and materials standards resources

- ASM International – Titanium and titanium alloys educational

- NACE International / AMPP – Corrosion fundamentals and industry guidance