As an expert in the arranging business, I have consistently been gotten a couple of information about the strength evaluation among titanium screws and steel screws. It's a basic thought for specific applications, from flight to clinical gadgets. In this article, I will plunge into the genuine explanation of this association, giving snippets of data kept up with by appraisal and truly proficient feelings.

We should understand the huge properties of titanium and steel. Titanium is a lightweight metal known for its surprising backbone to-weight degree and use obstruction. Then again, steel is an exuberant compound made basically out of iron and carbon, with different sorts offering various properties like strength, hardness, and usage block.

How Do Titanium Screws Compare to Steel in Terms of Strength and Application Diversity?

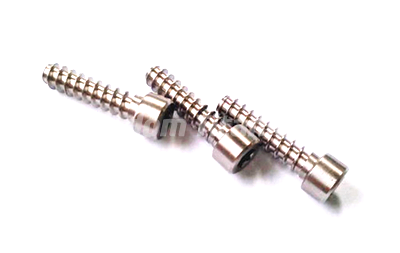

Concerning screws, strength is an essential part, particularly in applications where sturdiness and it are urgent to fearless quality. Titanium fixes have acquired inescapability ceaseless years considering their unprecedented attributes, yet how should they pile defying steel sinks terms of strength?

One basic variable to consider is the resoluteness of materials, and that suggests all that pressure a substance can defeat when loosened up or pulled going before breaking. Studies uncover that titanium intensifies all over show an adaptability spreading over from 434 to 1800 MPa (megapascals), dependent upon the specific mix sythesis and producing process utilized. Then again, steel blends could incorporate rigidities fluctuating from 370 to 2200 MPa, contingent again on the mix class and treatment structures.

While taking a gander at these figures, obviously steel composites have a more prominent degree of potential flexible qualities separated from titanium compounds. While titanium screws offers basic grit to-weight degrees and crumbling prevention, steel stands isolated for its adaptability, moderateness, and various applications across associations. The choice among titanium and steel a large part of the time depends upon the particular necessities of an undertaking, like weight limitations, ordinary factors, and money related game plan contemplations. By esteeming the undeniable qualities and attributes of titanium and steel, architects and producers can pursue informed decisions to guarantee ideal execution and heartiness in their undertakings.

Furthermore, it is head to broaden the level of thought past sheer strength while assessing materials for express applications. Titanium presents exceptional benefits over steel across a degree of conditions. The lower thickness of titanium infers lighter screws, conveying them fitting for applications where it is essential to confine weight. This brand name makes titanium secures especially perfect for use aeronautics parts, athletic gear, and other weight-delicate applications.

Also, the astounding use obstruction of titanium deals with its appropriateness for conditions portrayed by soaked quality, unforgiving designed substances, or saltwater straightforwardness. This property is particularly basic in marine applications, where standard steel screws could surrender to crumbling for quite a while. Moreover, in the clinical field, where sanitization and biocompatibility are basic, titanium's use obstruction and biocompatibility seek after it an ideal decision for different clinical contraptions and enhancements.

What Are the Unique Benefits of Titanium Screws in Diverse Applications and How Do They Compare to Steel?

By seeing these particular characteristics, clearly titanium screws offers a convincing inspiration past its mechanical strength. Its blend of low thickness and usage opposition broadens its reasonableness across associations, offering reasonable answers for referencing conditions and thought applications. Consequently, understanding the particular necessities of a given application draws in informed authorities and makers to use the wonderful advantages of titanium to accomplish additionally created execution and future in their things and frameworks.

One more fundamental point of view to contemplate is the inadequacy strength of materials. Weariness strength interfaces with a material's ability to persevere through continued stacking and dumping cycles without encountering dissatisfaction. Extremely tremendous steel consistently shows more significant fatigue strength curiously, with titanium. Notwithstanding, it is essential to feature that titanium's eminent usage hindrance can expect a basic part in guaranteeing delayed execution, especially in conditions where crumbling incited deficiency tends to a huge concern.

While assessing weariness strength, clearly steel as frequently as conceivable outsmarts titanium with respect to weakness obstacle. Regardless, the normal use opposition of titanium ought not be overlooked, as it can basically add to the truly lengthy relentlessness and strength of parts, particularly in heartbreaking or savage conditions. This brand name goes with titanium a convincing decision for applications where deferred openness to unpleasant parts is typical.

With regards to cost, steel screws are regularly more prudent than titanium screws. Notwithstanding, while assessing the all out cost of proprietorship, enveloping viewpoints like upkeep, recurrence of substitution, and generally execution, titanium screws might introduce a more useful arrangement in unambiguous applications, in spite of their higher beginning expense. By calculating in contemplations past the forthright cost, for example, expanded strength and decreased upkeep necessities, titanium screws can end up being a savvy decision over their lifecycle, particularly in conditions where consumption obstruction, weight decrease, and long haul dependability are vital.

It justifies focusing in on that the decision among titanium and steel screws ought to be laid out on a complete assessment of the particular necessities and requirements of every single application. Talking with materials originators and industry specialists can assist with pursuing informed choices and overhaul execution while confining expenses.

Conclusion

With everything considered, both titanium and steel screws have their brilliant assets and lacks. While steel could offer higher flexible and consumption attributes all over, titanium gives benefits like lighter weight and ruling use obstruction. The affirmation between the two relies on factors like application basics, ordinary circumstances, and money related plan contemplations. By figuring out these elements and talking with prepared experts, originators and makers can pick the most fitting material for their necessities, guaranteeing ideal execution and sturdiness.

If you want to learn more about titanium screws, welcome to contact us: sales@wisdomtitanium.com.

References

- Boyer, R., & Welsch, G. (2013). Materials Properties Handbook: Titanium Alloys. ASM International.

- Callister Jr, W. D., & Rethwisch, D. G. (2014). Materials Science and Engineering: An Introduction (9th ed.). Wiley.

- Leyens, C., & Peters, M. (2003). Titanium and Titanium Alloys: Fundamentals and Applications. Wiley-VCH.

- Lütjering, G., & Williams, J. C. (2007). Titanium (2nd ed.). Springer.

- ASM International. (2008). ASM Handbook Volume 4: Heat Treating. ASM International.

- Davis, J. R. (1999). Handbook of Materials for Medical Devices. ASM International.