When it comes to building or maintaining a high-performance bicycle, every component matters – right down to the smallest bolt. Titanium bicycle bolts have gained popularity among cycling enthusiasts and professionals alike due to their exceptional strength-to-weight ratio, corrosion resistance, and durability. In this comprehensive guide, we'll explore how different sizes of titanium bolts are suited for various parts of a bicycle, why bolt size matters in bicycle construction, and which sizes are best for specific components.

Why does bolt size matter in bicycle construction?

Bolt size is a critical factor in bicycle construction for several reasons:

1. Structural integrity: The right bolt size ensures that components are securely fastened, maintaining the bicycle's structural integrity under various riding conditions. Using bolts that are too small can lead to component failure, while oversized bolts may not fit properly or could damage the frame.

2. Weight optimization: In the world of cycling, every gram counts. Using appropriately sized titanium bolts helps minimize overall weight without compromising strength. This is particularly important for high-performance and racing bicycles where weight reduction can significantly impact speed and handling.

3. Compatibility: Different bicycle parts and components are designed to work with specific bolt sizes. Using the correct size ensures proper fit and function, reducing the risk of damage or malfunction.

4. Torque application: Bolt size affects the amount of torque that can be safely applied. Larger bolts can generally withstand higher torque values, which is crucial for components that experience high stress during riding.

5. Aesthetics: While functionality is paramount, the appearance of a bicycle is also important to many riders. Using the correct bolt sizes contributes to a clean, professional look.

Understanding the importance of bolt size in bicycle construction sets the foundation for selecting the right titanium bicycle bolts for various components. Let's explore the common sizes used in modern bicycles.

What are the common sizes of titanium bolts used in bicycles?

Titanium bicycle bolts come in a range of sizes to accommodate different components and applications. The most common sizes include:

1. M4: These small bolts are typically used for lightweight components and in areas where space is limited. Common applications include:

- Brake lever clamps

- Derailleur cable anchor bolts

- Some headset top caps

2. M5: This is one of the most widely used bolt sizes in modern bicycles. M5 titanium bolts are versatile and can be found in various lengths. They are commonly used for:

- Stem bolts (both steerer tube clamp and handlebar clamp)

- Water bottle cage mounts - Brake caliper mounting bolts

- Some seatpost clamps

3. M6: These larger bolts are used in areas that require more strength or support. Common applications include:

- Pedal spindles

- Some seatpost clamps

- Rear derailleur mounting bolts

- Some brake rotor bolts

4. M8: These are among the largest bolts commonly used in bicycles. They are typically found in high-stress areas or on larger components:

- Crank arm fixing bolts

- Some seatpost clamps (especially on mountain bikes)

- Some suspension pivot bolts

5. M10: While less common, M10 bolts are sometimes used for:

- Bottom bracket cups

- Some suspension components

It's important to note that bolt length can vary significantly within each size category, depending on the specific application. For example, M5 bolts used in stem faceplates might be 16mm long, while those used for water bottle cages could be 12mm or shorter.

When selecting titanium bicycle bolts, it's crucial to match not only the diameter (M4, M5, etc.) but also the length and thread pitch to the original bolt or the manufacturer's specifications. Using bolts that are too short can result in inadequate thread engagement, while overly long bolts may bottom out or interfere with other components.

Which titanium bolt sizes are best for the frame, handlebars, and stem?

Now that we've covered the common sizes of titanium bicycle bolts, let's focus on which sizes are best suited for critical components like the frame, handlebars, and stem.

Frame:

The frame is the backbone of any bicycle, and the bolts used here need to be carefully selected. Common titanium bolt sizes for frame components include:

- Water bottle cage mounts: Typically M5 x 12mm or M5 x 15mm

- Rear derailleur hanger: Usually M10 x 1mm thread pitch

- Disc brake mounts: Often M5 x 16mm or M6 x 18mm, depending on the frame design

- Rack mounts: Commonly M5 x 15mm or M5 x 20mm

For custom or specialized frames, always refer to the manufacturer's specifications, as some may use proprietary sizes or threading.

Handlebars:

Handlebar components require secure fastening while allowing for adjustments. Common titanium bolt sizes include:

- Brake lever clamps: Usually M5 x 16mm or M6 x 18mm

- Shifter clamps: Typically M5 x 12mm or M5 x 16mm

- Bar end plugs: Often M6 with varying lengths

The exact size may vary depending on the brand and model of the components. Always check the manufacturer's recommendations before replacing stock bolts with titanium alternatives.

Stem:

The stem is a critical component that connects the handlebars to the fork steerer tube. Proper bolt selection is crucial for safety and performance. Common titanium bolt sizes for stems include:

- Steerer tube clamp bolts: Usually M5 x 16mm or M5 x 18mm

- Faceplate bolts: Typically M5 x 16mm or M5 x 18mm

- Top cap bolt: Often M6 x 30mm or M6 x 35mm, but can vary

It's important to note that some high-performance stems may use slightly different sizes or proprietary bolts. Always consult the stem manufacturer's specifications before replacing bolts.

When upgrading to titanium bolts for these critical components, consider the following tips:

- Always use a torque wrench and follow the manufacturer's torque specifications.

- Apply a thin layer of anti-seize compound to prevent galling, which can occur between titanium bolts and aluminum components.

- Regularly inspect titanium bolts for signs of wear or damage, especially in high-stress areas.

- When in doubt, consult a professional bicycle mechanic or the component manufacturer for guidance on bolt selection and installation.

By choosing the right size and grade of titanium bolts for each application, you can optimize your bicycle's performance, reduce weight, and enhance durability. Remember that while titanium bolts offer many advantages, they should always be used in accordance with the bicycle and component manufacturers' recommendations to ensure safety and proper function.

Contact Wisdom Titanium

Titanium bolts offer a compelling blend of strength, light weight, and corrosion resistance that makes them an excellent choice for upgrading your bike. By understanding the different sizes and their applications, you can make informed decisions about which titanium bolts are best suited for various parts of your bicycle. Remember, while the allure of titanium is strong, always prioritize safety and follow manufacturer guidelines when making any modifications to your bike.

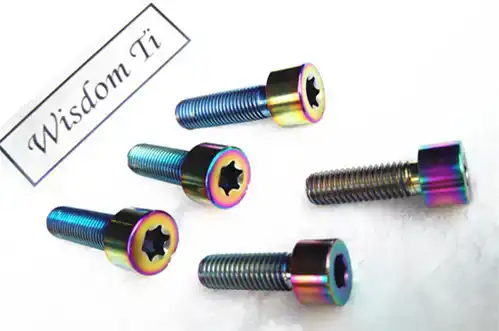

Are you ready to elevate your cycling experience with premium titanium bicycle bolts? Look no further than Wisdom Titanium for high-quality, precision-engineered titanium fasteners. Our range includes bolts suitable for frames, handlebars, stems, and more, all crafted to meet the exacting standards of professional cyclists and enthusiasts alike. Don't compromise on quality or performance – upgrade your ride with Wisdom Titanium bolts today. For personalized assistance in selecting the perfect titanium bolts for your bicycle, reach out to our expert team at sales@wisdomtitanium.com. Let's work together to optimize your bicycle's performance and take your riding to the next level!

References

[1] Mattox, D. M. (2010). Handbook of Physical Vapor Deposition (PVD) Processing. William Andrew.

[2] Yin, Y., & McKenzie, D. R. (2017). Comparison of titanium nitride coatings deposited by unbalanced magnetron sputtering and cathodic arc evaporation. Surface and Coatings Technology, 326, 346-353.

[3] Podgornik, B., Hogmark, S., & Sandberg, O. (2006). Proper coating selection for improved galling performance of forming tool steel. Wear, 261(1), 15-21.