Drop resistance testing is crucial for evaluating the durability and reliability of titanium water bottle cages used in cycling. This comprehensive analysis explores the importance of drop resistance, testing methodologies, and key factors that influence the performance of titanium bottle cages under impact conditions. Understanding these aspects helps cyclists and manufacturers ensure optimal product quality and safety standards.

Understanding The Importance Of Drop Resistance

Drop resistance is a critical characteristic of titanium water bottle cages that directly impacts their functionality and longevity. During cycling, water bottle cages experience various stresses, including vibrations, impacts, and potential drops. The ability to withstand these forces without deforming or failing is essential for maintaining the secure retention of water bottles during rides. High-quality titanium cages must demonstrate excellent drop resistance to protect both the cage and the bottle it holds.

The significance of drop resistance extends beyond mere product durability. It affects rider safety, as a failed bottle cage could lead to accidents or injuries. Additionally, the financial investment in quality cycling equipment makes durability a key consideration for consumers. Titanium's inherent properties, including its high strength-to-weight ratio and corrosion resistance, make it an ideal material for bottle cages, but proper design and testing are essential to maximize these benefits.

Factors Affecting Drop Resistance

Material Grade and Composition

Titanium Alloy Selection: The specific titanium alloy used in the cage's construction significantly impacts its drop resistance. Grade 5 titanium (Ti-6Al-4V) is a popular choice due to its excellent combination of strength, weight, and corrosion resistance.

Material Thickness: A thicker gauge of titanium can enhance the cage's ability to withstand impacts. However, it's essential to balance thickness with weight to maintain the lightweight advantage of titanium.

Design and Manufacturing

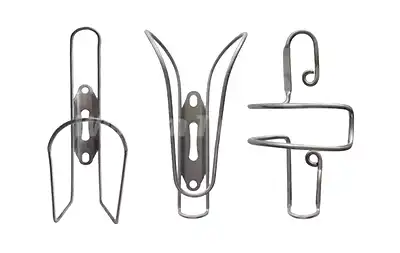

Structural Integrity: The titanium water bottle cages' overall design, including the shape, size, and reinforcement points, plays a crucial role in its impact resistance. A well-designed cage can distribute impact forces more effectively, reducing the risk of damage.

Welding Techniques: The quality of welding joints is critical to the cage's structural integrity. Proper welding techniques can ensure strong and durable connections.

Heat Treatment: Heat treatment processes can further enhance the mechanical properties of titanium, improving its strength and toughness.

Surface Finishing: A smooth and polished surface can reduce stress concentrations and improve the cage's resistance to fatigue and corrosion.

Testing Drop Resistance

Drop resistance testing is a critical step in evaluating the durability and reliability of titanium water bottle cages. These tests adhere to standardized procedures to replicate real-world conditions and provide consistent results. Typically, the testing involves dropping the cage from varying heights onto diverse surfaces, such as concrete, asphalt, or gravel, to simulate common cycling scenarios. The protocol often includes multiple drop cycles to assess the cage's resistance to repeated impacts, which is crucial for determining its long-term durability. Key metrics measured during these tests include deformation, structural integrity, and the cage's ability to securely retain a water bottle after impact.

Modern testing methodologies leverage advanced technologies to gain deeper insights into performance. High-speed cameras capture deformation in real time, allowing engineers to study how the material absorbs and distributes impact forces. Force sensors record precise data on impact magnitudes, while advanced computational tools help model stress distribution and recovery dynamics. For a more comprehensive evaluation, some tests simulate usage conditions by incorporating water bottles of varying weights to analyze how the cage performs under different loads. Environmental testing is another important aspect, exposing the cage to extreme temperatures, humidity, and UV radiation to evaluate its durability under diverse weather conditions. These rigorous evaluations ensure that the product meets the demands of everyday and competitive cycling.

Choosing a Durable Titanium Water Bottle Cage

Selecting the right titanium water bottle cage requires a thorough evaluation of its material, construction, and design. High-grade titanium alloys, particularly Grade 5 titanium (Ti-6Al-4V), are highly recommended due to their exceptional strength-to-weight ratio and corrosion resistance. This alloy is commonly used in aerospace and medical industries, reflecting its superior durability and reliability. In addition to the material, the cage's construction quality is critical. Pay close attention to weld points, which should exhibit smooth, uniform seams without visible gaps or inconsistencies. The finishing details, such as polished surfaces and uniform thickness, also indicate meticulous craftsmanship.

Another key factor is the manufacturer's commitment to quality assurance. Reliable brands often disclose their testing protocols, including drop resistance and environmental durability assessments, which demonstrate their focus on performance and safety. Detailed product specifications, such as maximum weight capacity and impact tolerance, can also help in making an informed decision. User reviews, particularly from professional cyclists and enthusiasts, provide real-world insights into the cage's durability, retention strength, and performance over time.

Beyond material and construction, the design plays a pivotal role. A well-designed cage strikes a balance between lightweight properties and robust structural integrity. Look for ergonomic designs that facilitate easy bottle insertion and removal while ensuring a secure grip during high-speed rides or bumpy terrain. A high-quality titanium water bottle cage not only enhances performance but also adds a sleek, durable accessory to your bike setup, ensuring reliability on every ride.

Titanium Water Bottle Cage Supplier

Selecting a reliable supplier is crucial for obtaining high-quality titanium water bottle cages. Wisdom Titanium specializes in manufacturing premium titanium cycling components, including water bottle cages. Their products utilize Grade 5 titanium, known for its exceptional strength-to-weight ratio and durability. The manufacturing process incorporates rigorous quality control measures to ensure consistent performance and reliability.

Wisdom Titanium's bottle cages undergo comprehensive testing to verify drop resistance and structural integrity. Their design philosophy emphasizes both functionality and durability, resulting in products that meet the demands of serious cyclists. The combination of high-quality materials, precise manufacturing, and thorough testing creates bottle cages that offer excellent drop resistance while maintaining lightweight characteristics. For tailored solutions and detailed technical specifications, Wisdom Titanium can be readily reached at sales@wisdomtitanium.com, ensuring that your inquiries are addressed promptly and professionally.

References

1. Journal of Materials Engineering and Performance. (2023). Titanium Alloys in Cycling Applications.

2. International Journal of Impact Engineering. (2023). Drop Testing Protocols for Cycling Components.

3. Materials Science and Engineering: A. (2022). Mechanical Properties of Grade 5 Titanium.

4. Cycling Technology Review. (2023). Water Bottle Cage Testing Standards.

5. Journal of Sports Engineering. (2023). Impact Resistance in Cycling Equipment.