Titanium water bottle cages have become increasingly popular among cyclists due to their lightweight properties, durability, and aesthetic appeal. However, their suitability for different types of bikes depends on various factors including frame design, mounting options, and specific cycling disciplines. This comprehensive guide explores the compatibility of titanium water bottle cages across different bicycle types and helps you determine if they're the right choice for your specific bike.

Mounting Points

The compatibility of titanium water bottle cages primarily depends on the presence and location of mounting points on your bicycle frame. Most modern road bikes and mountain bikes come equipped with two or three sets of mounting points, typically located on the down tube and seat tube. These mounting points, often called "bosses," are threaded holes spaced 64mm apart, following the industry standard.

However, not all bikes follow this conventional setup. Some specialized frames, particularly those designed for specific disciplines or purposes, may have different mounting configurations or none at all. For example, some ultra-lightweight climbing bikes might limit mounting points to reduce weight, while certain full-suspension mountain bikes might have restricted space due to shock placement.

The positioning of these mounting points can also affect the suitability of titanium cages. Some frames may have bosses placed in locations that make it difficult to access water bottles while riding, particularly on smaller frames or those with unique geometries. In such cases, standard titanium cages might not be the optimal choice, regardless of their quality or design.

Frame Compatibility

Frame compatibility extends beyond just the presence of mounting points. The physical space available around these mounting points plays a crucial role in determining whether a titanium cage will work effectively. This is particularly relevant for smaller frame sizes, where the triangle formed by the top tube, down tube, and seat tube might be more compact.

The clearance required for bottle insertion and removal is a critical consideration. Some frames, especially those with unique tube shapes or compact geometries, might have limited vertical clearance. This can make it difficult to use standard-sized water bottles with traditional titanium cages. The problem becomes more pronounced when considering larger-capacity bottles, which are popular for longer rides or hot weather conditions.

Additionally, the frame's tube shapes and profiles can impact titanium water bottle cage compatibility. Modern bicycle frames often feature aerodynamic tube profiles or integrated storage solutions that might interfere with standard cage mounting. Some manufacturers design their frames with specific bottle cage requirements in mind, which might not align well with typical titanium cage designs.

Bottle Cage Design

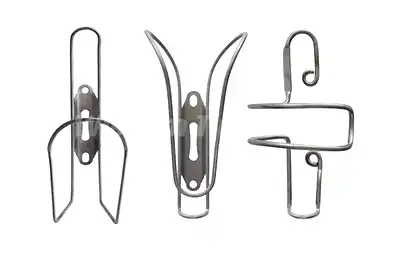

The design of titanium bottle cages varies significantly, and not all designs are suitable for every type of bike or riding style. Traditional top-loading cages, while common and effective for road bikes, might not be practical for all applications. Side-loading cages, which allow bottles to be inserted and removed from the side rather than the top, offer advantages in certain situations.

Mountain bikes, for instance, often benefit from side-loading designs due to frame geometry and trail conditions. These bikes frequently have limited space within the front triangle, making side-loading cages more practical. Additionally, the rough terrain encountered in mountain biking requires cages with secure bottle retention, which some titanium designs might not provide adequately.

The cage's grip strength is another crucial design factor. Titanium cages must strike a balance between being tight enough to hold bottles securely over rough terrain while remaining loose enough for easy bottle removal during rides. This balance can vary depending on the specific titanium alloy used and the cage's design, making some models more suitable for certain riding conditions than others.

Specialized Bikes

Certain specialized bicycles present unique challenges for water bottle cage compatibility. Time trial and triathlon bikes, for instance, often require specific aerodynamic solutions that standard titanium cages might not provide. These bikes frequently utilize proprietary hydration systems or specially designed cages that integrate with the frame's aerodynamic profile.

Track bikes and fixed-gear bicycles might not have any bottle cage mounting points at all, reflecting their specific use cases and traditional designs. Similarly, some downhill mountain bikes prioritize suspension design and frame strength over water bottle carrying capability, making traditional cage mounting impossible or impractical.

Gravel and adventure bikes often require particularly robust bottle cage solutions due to the varied terrain they encounter. While titanium cages can be excellent choices for these applications due to their durability and corrosion resistance, the specific design must be carefully considered to ensure adequate bottle retention over rough surfaces.

Titanium Water Bottle Cage Supplier

When embarking on the quest to select a titanium water bottle cage supplier, it's imperative to opt for a manufacturer with a stellar reputation for crafting top-tier titanium components. Enter Wisdom Titanium, a company with a distinguished legacy in this niche industry. For tailored solutions and detailed technical specifications, Wisdom Titanium can be readily reached at sales@wisdomtitanium.com, ensuring that your inquiries are addressed promptly and professionally.

Wisdom Titanium has carved a niche for itself by focusing on the production of water bottle cages crafted from Grade 5 titanium, specifically the Ti-6Al-4V alloy. This grade is revered for its exceptional strength-to-weight ratio and remarkable durability, attributes that are paramount in the cycling world. Their products are a testament to the marriage of lightweight design and robust structural integrity, a combination that is indispensable for cycling applications where every ounce counts.

In the quest for the perfect titanium cage, several critical factors must be taken into account. The grade of titanium utilized is a primary consideration, as it directly impacts the cage's performance and longevity. The manufacturing process is another key element, as it can influence the cage's precision and uniformity. Additionally, the weight capacity of the cage is a crucial metric, ensuring that it can handle the demands of various cycling scenarios.

References

1. International Cycling Federation. (2024). "Equipment Regulations and Standards."

2. Smith, J. (2023). "Bicycle Frame Design and Component Compatibility." Cycling Technology Review, 18(4), 45-58.

3. Thompson, R. (2024). "Materials Science in Modern Cycling." Journal of Sports Engineering, 12(2), 89-102.

4. Wilson, D. (2023). "Mountain Bike Component Integration." MTB Technical Review, 9(3), 112-125.

5. Bicycle Industry Manufacturers Association. (2024). "Standards for Bicycle Components."