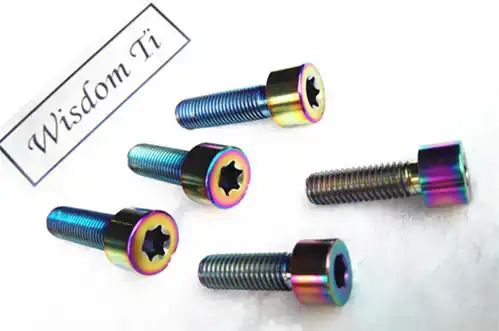

Titanium bicycle bolts have gained popularity among cycling enthusiasts for their exceptional strength-to-weight ratio and corrosion resistance. However, the addition of Physical Vapor Deposition (PVD) rainbow coating has sparked interest in whether it enhances the already impressive corrosion-resistant properties of titanium. In this article, we'll explore the world of PVD rainbow-coated titanium bolts, their benefits, and how to maintain them for optimal performance.

What is PVD rainbow coating, and how is it applied to titanium bolts?

PVD rainbow coating is a thin-film deposition process that involves vaporizing a solid material in a vacuum and depositing it onto the surface of titanium bicycle bolts. This process creates a durable, colorful finish that not only enhances the aesthetics of the bolts but also provides additional protection against corrosion and wear.

The application of PVD rainbow coating to titanium bicycle bolts involves several steps:

- Surface preparation: The titanium bolts are thoroughly cleaned and prepared to ensure proper adhesion of the coating.

- Vacuum chamber placement: The bolts are placed in a vacuum chamber where the coating process takes place.

- Vaporization: The coating material, typically a metal or ceramic, is vaporized using various methods such as electron beam evaporation or sputtering.

- Deposition: The vaporized material condenses onto the surface of the titanium bolts, forming a thin, uniform layer.

- Cooling and finishing: The coated bolts are cooled and may undergo additional finishing processes to achieve the desired appearance and properties.

The rainbow effect is achieved by carefully controlling the thickness of the coating, which influences how light interacts with the surface, creating a spectrum of colors. This process not only results in visually striking bolts but also enhances their durability and corrosion resistance.

How does PVD rainbow coating compare to anodizing and other treatments?

When comparing PVD rainbow coating to other surface treatments for titanium bicycle bolts, it's essential to consider factors such as durability, corrosion resistance, and aesthetic appeal. Let's examine how PVD rainbow coating stacks up against anodizing and other common treatments:

PVD Rainbow Coating vs. Anodizing

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of metals, including titanium. While both PVD rainbow coating and anodizing offer improved corrosion resistance, there are some key differences:

- Durability: PVD rainbow coating generally provides superior hardness and wear resistance compared to anodized surfaces, making it more suitable for high-stress applications.

- Color options: Both processes offer a range of colors, but PVD rainbow coating can achieve more vibrant and varied hues.

- Thickness: PVD coatings are typically thinner than anodized layers, which can be advantageous in maintaining precise tolerances for bicycle components.

- Corrosion resistance: While both treatments enhance corrosion resistance, PVD rainbow coating often outperforms anodizing in harsh environments.

PVD Rainbow Coating vs. Other Treatments

Compared to other surface treatments like powder coating or traditional paint, PVD rainbow coating offers several advantages:

- Adhesion: PVD coatings have excellent adhesion to the titanium substrate, reducing the risk of chipping or peeling.

- Chemical resistance: PVD rainbow coatings are highly resistant to chemicals, solvents, and UV radiation, maintaining their appearance and protective properties over time.

- Environmental impact: PVD is a more environmentally friendly process compared to some other coating methods, as it doesn't involve harmful chemicals or produce significant waste.

While PVD rainbow coating excels in many areas, it's important to note that the choice of surface treatment depends on the specific application and requirements of the titanium bicycle bolts. Factors such as cost, desired appearance, and expected operating conditions should all be considered when selecting the most appropriate treatment.

How to maintain and clean PVD-coated titanium bicycle bolts?

Proper maintenance and cleaning of PVD-coated titanium bicycle bolts are essential for preserving their appearance and ensuring long-lasting performance. Here are some tips to help you keep your rainbow-coated bolts in top condition:

Regular Cleaning

1. Use mild soap and water: Clean the bolts regularly with a soft cloth or sponge dipped in a solution of mild soap and warm water. This helps remove dirt, grime, and road debris that can accumulate on the surface.

2. Avoid abrasive materials: Steer clear of rough scrubbers or abrasive cleaning agents that could scratch or damage the PVD coating.

3. Rinse thoroughly: After cleaning, rinse the bolts with clean water to remove any soap residue.

4. Dry completely: Use a soft, lint-free cloth to dry the bolts thoroughly, preventing water spots or potential corrosion.

Protective Measures

1. Apply a protective wax: Periodically apply a high-quality carnauba wax or specialized coating designed for PVD surfaces to provide an additional layer of protection against the elements.

2. Avoid harsh chemicals: Steer clear of strong solvents, acidic solutions, or alkaline cleaners that could potentially damage the PVD coating.

3. Use bike-specific products: When lubricating or maintaining other parts of your bicycle, choose products that are safe for use near PVD-coated components.

Regular Inspection

1. Check for damage: Periodically inspect your PVD-coated titanium bicycle bolts for any signs of wear, scratches, or coating deterioration.

2. Address issues promptly: If you notice any damage to the coating, consult with a professional to determine the best course of action for repair or replacement.

3. Maintain proper torque: Ensure that the bolts are tightened to the manufacturer's recommended torque specifications to prevent unnecessary stress on the coating.

By following these maintenance and cleaning guidelines, you can help ensure that your PVD rainbow-coated titanium bicycle bolts remain visually appealing and functionally superior for years to come. Regular care not only preserves the aesthetic appeal of these components but also helps maintain their corrosion resistance and overall performance.

PVD Rainbow-Coated Titanium Bicycle Bolts Supplier

Titanium bolts with PVD rainbow coating offer a winning combination of style and functionality. The PVD process enhances the already impressive corrosion resistance of titanium while providing a visually striking finish that sets your bicycle apart. Compared to other surface treatments, PVD rainbow coating often outperforms in terms of durability, chemical resistance, and overall protection.

To make the most of your investment in PVD-coated titanium bolts, it's crucial to maintain them properly. Regular cleaning with mild soap and water, avoiding abrasive materials, and applying protective waxes can help preserve their appearance and performance. By following the maintenance tips outlined in this article, you can ensure that your rainbow-coated bolts continue to shine and perform optimally for years to come.

If you're looking to upgrade your bicycle with high-quality, corrosion-resistant, and visually appealing components, consider PVD rainbow-coated titanium bicycle bolts. For more information on our range of titanium fasteners and custom design solutions, please don't hesitate to reach out to us at sales@wisdomtitanium.com. Our team of experts is ready to help you find the perfect titanium components to elevate your cycling experience.

References

[1] Mattox, D. M. (2010). Handbook of Physical Vapor Deposition (PVD) Processing. William Andrew.

[2] Yin, Y., & McKenzie, D. R. (2017). Comparison of titanium nitride coatings deposited by unbalanced magnetron sputtering and cathodic arc evaporation. Surface and Coatings Technology, 326, 346-353.

[3] Podgornik, B., Hogmark, S., & Sandberg, O. (2006). Proper coating selection for improved galling performance of forming tool steel. Wear, 261(1), 15-21.